As we enter the middle of 2023, Pakistan is grappling with an uncontrollable depreciation of its currency, which is significantly impacting the automotive industry and leading to skyrocketing prices of new cars.The dream of owning a new car has become increasingly distant, and even purchasing a used vehicle now requires substantial savings. Let’s delve into the current state of affairs and explore what lies ahead for Pakistan’s automotive industry, along with some key facts about the present scenario.

What’s Causing the Price Surge? Over the past two years, Pakistan has witnessed consistent price increases in the automotive sector. The rising prices of cars and motorcycles are often attributed to the fluctuating value of the US Dollar, which affects production costs, utilities, labor rates, and raw materials, among other factors.

However, it is worth considering whether these commonly cited reasons are truly the underlying cause of the ongoing price hikes.

The Pakistan Association of Parts and Accessories Manufacturers (PAAPAM) hired a financial consultancy firm to investigate the rapid price hikes, and their findings revealed that approximately 70-80% of parts, from engines to assemblies, are imported. The so-called “localizations” primarily involve cosmetic parts designed only for Pakistani variants that are no longer in production globally. Even the 41-year-old Bolan (Dabba) model has only 50% localized parts.

Localization plays a crucial role for car manufacturers as it allows them to avoid continuously raising vehicle prices whenever the value of the Pakistani rupee depreciates against the US dollar.

Inflation and Price Increases If companies genuinely prioritize localization, as they claim to, there should be a noticeable impact on vehicle prices during exchange rate fluctuations.

While it is true that raw materials and manufacturing costs may experience price increases, the subsequent jumps in prices should not be as steep as those witnessed between 2022 and 2023. For example, Indus Motors Toyota raised prices more than five times from January to May 2023. These significant and frequent price hikes raise doubts about the extent of localization efforts and their actual influence on stabilizing vehicle prices.

Concrete evidence and transparency are necessary to validate manufacturers’ claims regarding their localization initiatives.

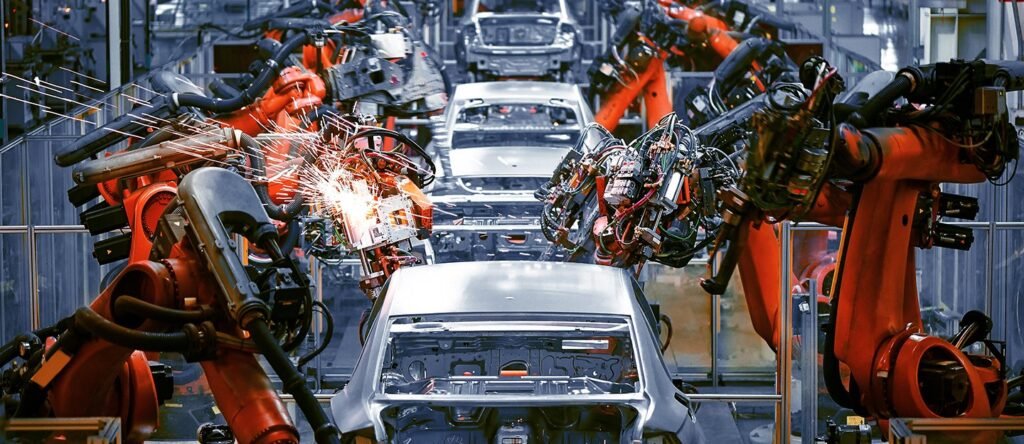

Raw Materials and Price Increases A closer examination of the components used in car manufacturing reveals that they are not made from super rare earth elements but rather from materials such as steel, plastic, electric components, and rubber.

Cars worldwide are manufactured using these materials along with substantial investment in research and development (R&D), which is where companies incur significant costs. R&D sets one company apart from another, such as Honda and Toyota.

However, in Pakistan, we are receiving decade-old models, so it’s primarily just raw materials and an outdated manufacturing process. While recent increases in the dollar exchange rate have raised prices across the board, the skyrocketing car prices far exceed the change in raw material prices.

Ban on Imports and Letters of Credit (LCs) and Price Increases Despite the Pakistani government’s efforts to encourage new entrants into the country’s automotive industry by reducing import duties on Completely Knocked Down (CKD) and Semi-Knocked Down (SKD) kits for the initial five years, a recent ban on opening Letters of Credit (LCs) has had a detrimental effect.

This ban has disrupted both the manufacturing and import of auto parts, categorizing cars and car parts as “Non-Essential Items” and leading to a temporary closure of the automotive industry, resulting in the unfortunate loss of millions of jobs. This situation is having an adverse impact on both the industry and the overall economy.

Who Benefits from Price Increases? When the Covid-19 pandemic spread across